Could a ‘spectral fingerprint’ revolutionize how we verify authenticity and quality?

Nearly 20% of food is lost or wasted globally each year due to spoilage and contamination, costing the world economy nearly $1 trillion. But what if we could ‘see’ imperfections invisible to the naked eye, instantly identifying defects and ensuring product integrity? A new generation of hyperspectral cameras, powered by artificial intelligence, is poised to do just that – and its impact will extend far beyond the food industry.

The Rise of Hyperspectral Vision

Traditional imaging captures color information – red, green, and blue – providing a visual representation of an object. Hyperspectral imaging, however, goes much deeper. It captures hundreds of narrow, contiguous spectral bands, creating a detailed ‘spectral fingerprint’ for every point in an image. This data reveals the chemical composition of materials, allowing for precise identification and analysis. Combined with the power of AI, this technology is becoming increasingly compact, energy-efficient, and deployable in real-world applications.

The OASYS project, led by the Fraunhofer Institute for Photonic Microsystems IPMS, is at the forefront of this innovation. Their work focuses on developing an ultra-compact hyperspectral camera that leverages AI to analyze spectral characteristics in real-time. Instead of analyzing every pixel, the system uses AI to identify ‘regions of interest’ – areas where detailed analysis is needed – significantly reducing processing time and energy consumption.

How Does it Work? A Two-Step Process

The process is elegantly simple. First, a standard 2D camera captures a high-resolution image. Then, AI algorithms analyze this image, pinpointing areas requiring further investigation. Finally, an integrated spectrometer performs a detailed spectral analysis on those specific regions, revealing the material’s chemical makeup. This targeted approach is a game-changer, making hyperspectral imaging practical for a wider range of applications.

Applications Across Industries

The potential applications of this technology are vast. Here are just a few examples:

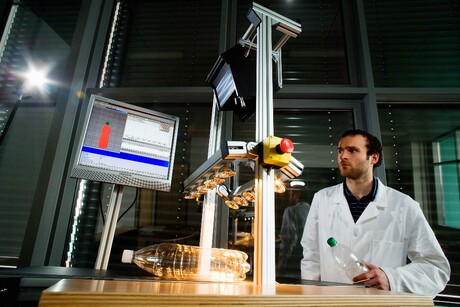

- Food Processing: Detecting subtle bruising, contamination, or variations in ripeness that are invisible to the human eye, ensuring food safety and quality.

- Textile and Plastic Recycling: Accurately sorting materials based on their composition, improving recycling efficiency and reducing waste.

- Counterfeit Detection: Identifying fake products by analyzing their chemical signatures, protecting consumers and brands.

- Agriculture: Assessing plant health, identifying nutrient deficiencies, and optimizing irrigation and fertilization strategies.

According to a recent report by Market Research Future, the global hyperspectral imaging market is projected to reach $2.4 billion by 2030, driven by increasing demand for quality control and advanced analytics across various industries.

The Future of Spectral Analysis: Miniaturization and Edge Computing

The current trend is towards even smaller, more energy-efficient hyperspectral cameras. This miniaturization will enable integration into a wider range of devices, from smartphones to drones. Furthermore, the rise of edge computing will allow for real-time analysis directly on the device, eliminating the need for cloud connectivity and reducing latency.

Beyond Quality Control: Predictive Analytics and Personalized Solutions

The future of hyperspectral imaging extends beyond simply identifying problems. By analyzing spectral data over time, we can develop predictive models to anticipate issues before they arise. In agriculture, for example, this could mean predicting crop yields and optimizing resource allocation. In manufacturing, it could mean identifying potential equipment failures before they occur.

We can also envision personalized solutions tailored to specific needs. Imagine a hyperspectral scanner in your kitchen that analyzes the nutritional content of your food, providing personalized dietary recommendations. Or a handheld device that assesses your skin health, identifying potential issues and suggesting appropriate treatments.

Frequently Asked Questions

What is the difference between hyperspectral and multispectral imaging?

While both capture data beyond the visible spectrum, hyperspectral imaging captures hundreds of narrow bands, providing a much more detailed spectral signature than multispectral imaging, which typically captures a few broader bands.

Is hyperspectral imaging expensive?

Historically, hyperspectral imaging systems were very expensive. However, advancements in technology, like the work being done by the OASYS project, are driving down costs and making the technology more accessible.

What are the limitations of hyperspectral imaging?

Data processing can be computationally intensive, requiring significant processing power and storage capacity. However, advancements in AI and edge computing are helping to overcome this challenge.

How does AI improve hyperspectral imaging?

AI algorithms can automatically identify regions of interest, reducing the amount of data that needs to be analyzed and improving the efficiency of the process. AI can also be used to classify materials and identify patterns that would be difficult for humans to detect.

The development of compact, AI-powered hyperspectral imaging systems represents a significant leap forward in sensor technology. As the cost of these systems continues to fall and their capabilities continue to expand, we can expect to see them deployed in an increasingly wide range of applications, transforming industries and improving our lives. What new applications can you envision for this powerful technology?

Explore more about the latest advancements in sensor technology in our guide to advanced materials.