New Recycling Method Uses Mechanical Force to break Down Plastics

Table of Contents

- 1. New Recycling Method Uses Mechanical Force to break Down Plastics

- 2. How does CCR address the limitations of plastic quality degradation inherent in conventional mechanical recycling methods?

- 3. Efficient Plastic Recycling Through Controlled Collisions: A Breakthrough Method Transforming Waste Management

- 4. Understanding the Limitations of Traditional plastic Recycling

- 5. The Science Behind Controlled Collision Recycling

- 6. Types of Plastics Effectively recycled with CCR

- 7. Benefits of Controlled collision Recycling

- 8. Real-World Applications and Case Studies

- 9. Addressing Challenges and Future Outlook

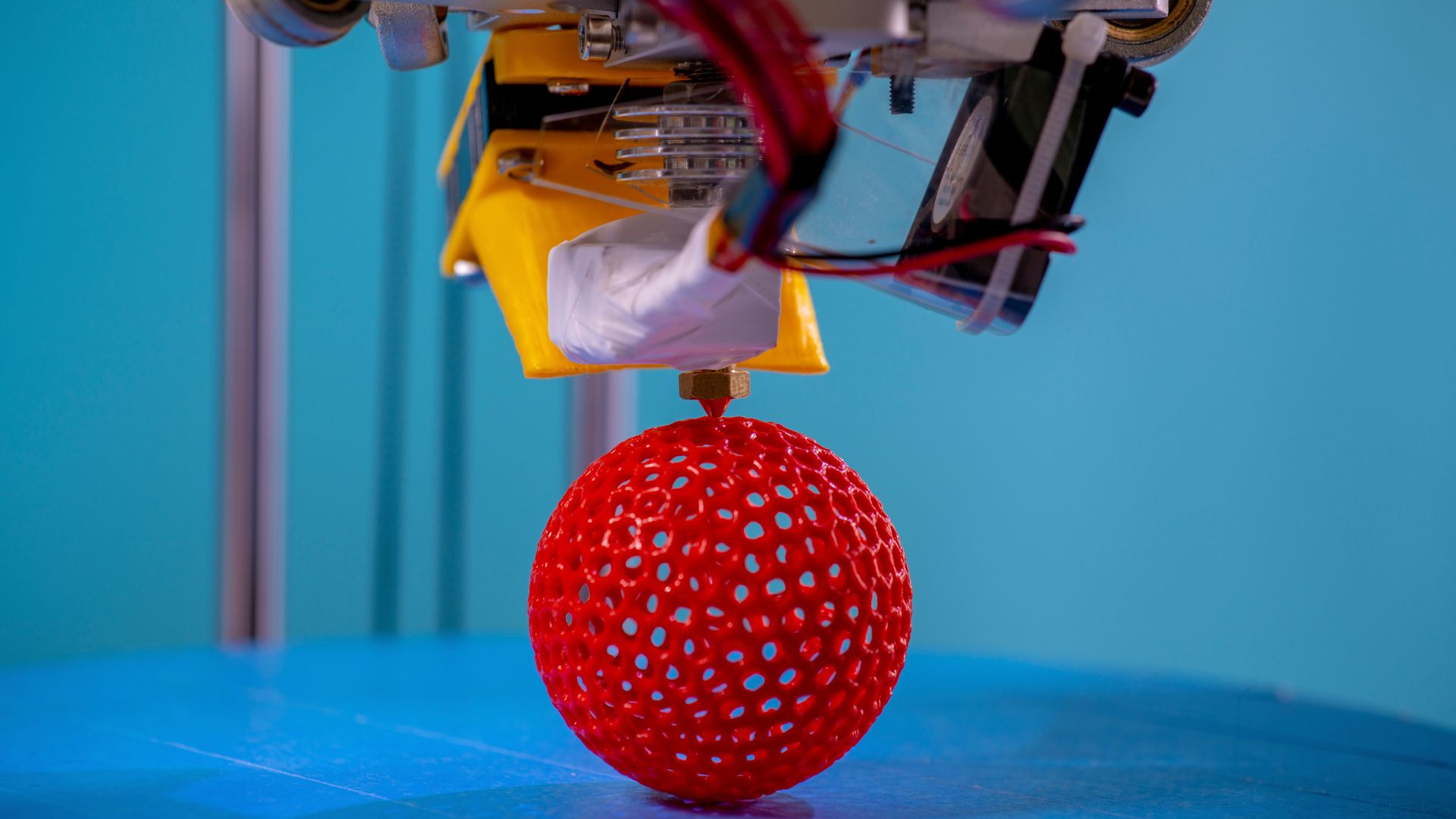

ATLANTA,GA – researchers at Georgia Tech have developed a groundbreaking method for recycling polyethylene terephthalate (PET),one of the world’s most common plastics,utilizing mechanical force rather of customary heat or harsh chemicals. This innovation offers a pathway towards faster, cleaner, and more sustainable plastic recycling, addressing the growing global concern of plastic accumulation in landfills and the environment.

PET, widely used in bottles, food packaging, and clothing fibers, is notoriously difficult to recycle efficiently due to its durability. The new research, published in the journal chem, details a “mechanochemical” approach – driving chemical reactions through mechanical forces like collisions – that rapidly breaks down PET into its basic building blocks at room temperature.

The team, led by postdoctoral researcher Kinga Gołąbek and Professor Carsten Sievers, subjected solid pieces of PET to impacts from metal balls within a ball mill, mimicking industrial conditions. These collisions, combined with solid chemicals like sodium hydroxide (NaOH), generate sufficient energy to break the plastic’s chemical bonds without requiring hazardous solvents.

“We’re showing that mechanical impacts can help decompose plastics into thier original molecules in a controllable and efficient way,” explains Sievers. “This could transform the recycling of plastics into a more sustainable process.”

Through controlled impact experiments and advanced computer simulations, researchers mapped the distribution of energy across the plastic during collisions, revealing how it triggers chemical and structural transformations. The impact creates tiny craters were the plastic stretches, cracks, and softens, fostering ideal conditions for reaction with sodium hydroxide.

High-resolution imaging revealed that the normally ordered polymer chains become disordered within these craters, with some breaking into smaller fragments, increasing the surface area available for reaction. Importantly, the study demonstrated that even without chemical reactants, mechanical force alone can initiate some degree of chain breaking.

“This understanding could help engineers design industrial-scale recycling systems that are faster,cleaner,and more energy-efficient,” says Gołąbek.the research highlights the critical role of impact energy, with stronger collisions leading to more significant cracking and plastic decomposition.

This innovative approach represents a significant step forward in addressing the global plastic waste crisis, offering a possibly transformative solution for a more sustainable future.

How does CCR address the limitations of plastic quality degradation inherent in conventional mechanical recycling methods?

Efficient Plastic Recycling Through Controlled Collisions: A Breakthrough Method Transforming Waste Management

Understanding the Limitations of Traditional plastic Recycling

Traditional plastic recycling methods, while well-intentioned, face notable hurdles. Mechanical recycling – the most common approach – frequently enough degrades plastic quality with each cycle, limiting its reuse potential. Chemical recycling, though promising, can be energy-intensive and costly. Consequently, a substantial portion of plastic waste still ends up in landfills or contributes to environmental pollution. This necessitates innovative solutions for plastic waste management and improved recycling technologies.the current global plastic pollution crisis demands a paradigm shift.

The Science Behind Controlled Collision Recycling

Controlled Collision Recycling (CCR) represents a novel approach to plastic recycling.This method leverages precisely engineered impacts to separate different types of plastics at a molecular level, enhancing purity and enabling higher-quality recycled materials.

HereS how it works:

- Waste Stream Planning: Mixed plastic waste undergoes initial sorting to remove contaminants like metals, glass, and paper. This pre-processing is crucial for optimal CCR performance.

- Controlled Impact Chamber: The plastic mixture enters a chamber where it’s subjected to a series of controlled collisions. The energy and frequency of these impacts are carefully calibrated based on the plastic types present.

- Molecular Separation: The collisions induce fracturing along polymer chain boundaries, effectively separating different plastic resins (PET, HDPE, PVC, LDPE, PP, PS).This is a key differentiator from traditional mechanical shredding.

- Density-Based Sorting: Following the collision process, density separation techniques are employed to further refine the plastic streams.

- Reprocessing & Upcycling: The highly purified plastic fractions are then ready for reprocessing into new products,frequently enough achieving quality comparable to virgin plastic. This facilitates closed-loop recycling systems.

Types of Plastics Effectively recycled with CCR

CCR demonstrates efficacy across a broad spectrum of plastic types, including those traditionally difficult to recycle:

* PET (Polyethylene Terephthalate): Commonly found in bottles and containers. CCR yields high-purity PET suitable for food-grade packaging.

* HDPE (high-Density Polyethylene): Used in milk jugs, detergent bottles, and pipes.CCR produces HDPE with excellent mechanical properties.

* PP (Polypropylene): Found in yogurt containers, bottle caps, and automotive parts. CCR enables the creation of durable PP products.

* LDPE (Low-Density Polyethylene): Used in plastic bags and films. CCR offers a viable pathway for recycling previously challenging LDPE waste.

* PS (Polystyrene): Often found in foam packaging and disposable cups. CCR can break down polystyrene into its monomer components for reuse.

* Mixed Plastics: CCR excels at processing complex plastic mixtures, reducing the need for extensive pre-sorting. This is a significant advantage in real-world waste sorting scenarios.

Benefits of Controlled collision Recycling

The advantages of CCR extend beyond improved recycling rates:

* Enhanced Purity: CCR delivers significantly purer plastic fractions compared to traditional methods, leading to higher-quality recycled products.

* Reduced Energy Consumption: While initial energy input is required for the collisions, the overall energy footprint can be lower than chemical recycling processes.

* Lower costs: CCR has the potential to be more cost-effective than chemical recycling, making it a more accessible solution for widespread adoption.

* Increased Recycling Rates: By effectively processing mixed plastics and difficult-to-recycle materials, CCR can dramatically increase overall plastic recycling rates.

* Reduced Landfill Waste: Diverting more plastic from landfills minimizes environmental impact and conserves valuable resources.

* Supports a Circular Economy: CCR promotes a circular economy for plastics, reducing reliance on virgin materials and minimizing waste.

Real-World Applications and Case Studies

While still an emerging technology, CCR is gaining traction with several pilot projects underway globally.

* Renewlogy (USA): This company is pioneering CCR technology, demonstrating successful recycling of mixed plastic waste into valuable feedstock for new products. Their process focuses on converting plastic waste into waxes, fuels, and other valuable materials.

* Fraunhofer Institute (Germany): Researchers at fraunhofer are developing advanced CCR systems optimized for specific plastic waste streams.Their work focuses on optimizing collision parameters for maximum separation efficiency.

* Municipal Pilot Programs: Several cities are exploring the integration of CCR into their existing waste management infrastructure to enhance recycling capabilities.

Addressing Challenges and Future Outlook

Despite its promise, CCR faces challenges:

* Scalability: Scaling up CCR technology to handle large volumes of plastic waste requires significant investment and infrastructure development.

* contaminant Management: Effective pre-sorting to remove contaminants remains crucial for optimal CCR performance.

* Public Awareness: Educating the public about the benefits of CCR and promoting its adoption is essential.

Looking ahead, advancements in automation, artificial intelligence (AI), and materials science will further refine CCR technology.AI-powered sorting systems can improve pre-processing efficiency, while advanced materials