Northrop Grumman Advances Space Logistics with Robotic Servicing Vehicle

Table of Contents

- 1. Northrop Grumman Advances Space Logistics with Robotic Servicing Vehicle

- 2. Robotics Integration: A Leap in Satellite Servicing

- 3. The Future of On-Orbit Servicing

- 4. Key Components and Technologies

- 5. Comparing Satellite Servicing Capabilities

- 6. Environmental Testing: Ensuring Reliability in Space

- 7. The Evergreen Impact of Space Logistics

- 8. Frequently Asked questions About Space Logistics

- 9. What are the potential risks associated with the widespread deployment of the NGRSS, considering the possibility of malfunction or misuse?

- 10. northrop Grumman’s next-Gen Space Robotic Servicing System: Orbital Servicing & Beyond

- 11. The Revolutionary Impact of Space Robotics

- 12. key Components and Capabilities of the NGRSS

- 13. Detailed Look at Space Robotic Missions

- 14. Northrop Grumman’s Legacy in Space Robotics

- 15. Benefits of the NGRSS

- 16. Real-World Examples and Case Studies of Space Robotic servicing

- 17. Impact on the Future of Space Exploration

- 18. Practical Tips for Space Robotics Enthusiasts

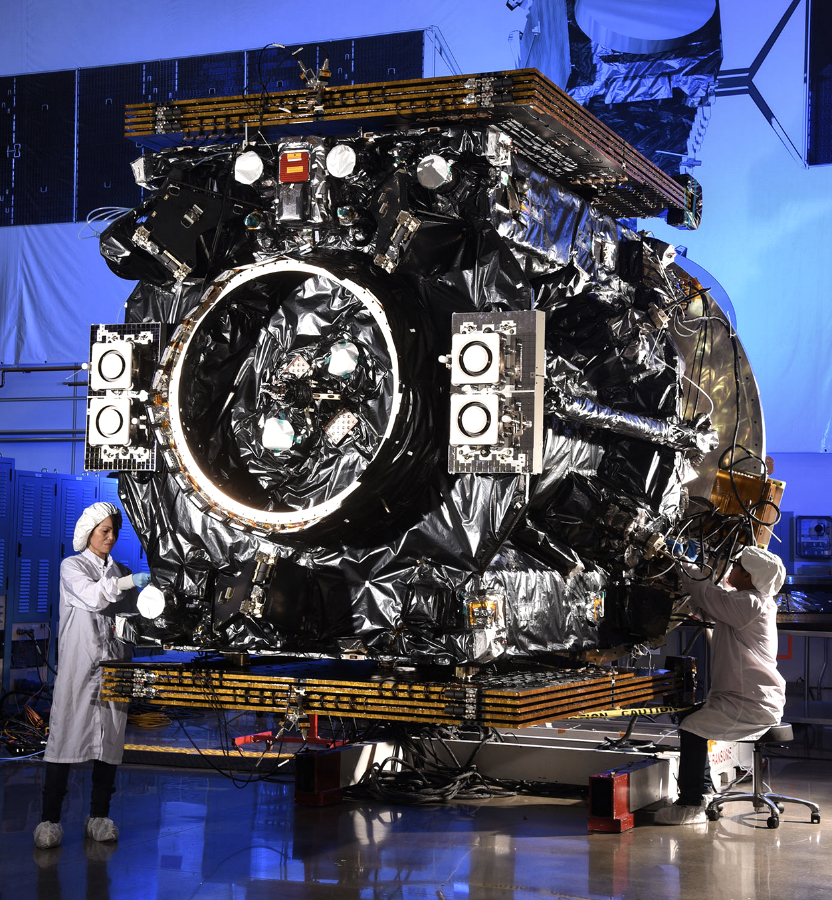

Dulles, Virginia-Northrop Grumman Corporation’s spacelogistics LLC has achieved a meaningful milestone by integrating a robotics payload onto its Mission Robotic Vehicle (MRV). This advancement is a crucial step in the Defense Advanced Research Project Agency’s (DARPA) Robotic Servicing of Geosynchronous Satellites (RSGS) program,heralding a new era of on-orbit satellite servicing.

Robotics Integration: A Leap in Satellite Servicing

The integration of the U.S. Naval Research Laboratory’s (NRL) robotics payload onto the MRV signifies a major advancement in space logistics.Northrop Grumman’s MRV is poised to become the first commercial spacecraft equipped with robotic servicing capabilities for both commercial and government satellites operating in Geosynchronous Equatorial Orbit (GEO).

Following the triumphant integration, the MRV will undergo rigorous environmental testing to ensure its performance and reliability in the harsh conditions of space.

The Future of On-Orbit Servicing

Rob Hauge, President of SpaceLogistics, emphasized the company’s vision for the future of satellite operations. “Innovative. Flexible. Adaptable.that is how we see the future of on-orbit servicing, and it is why we are the leading industry advocate for a model of future satellite operations that increases value for our customers,” Hauge stated. “With advanced robotics technology and our proven experience in satellite servicing, we are delivering the next generation of in-space sustainment technologies.”

Key Components and Technologies

The MRV builds upon Northrop Grumman’s established satellite servicing technology. The robotic payload from the NRL enhances the vehicle’s capabilities,allowing for more complex and versatile servicing missions.

This integration marks a pivotal moment in the evolution of space logistics, promising more sustainable and efficient satellite operations.

Comparing Satellite Servicing Capabilities

| Feature | Northrop Grumman’s MRV | Traditional Satellites |

|---|---|---|

| Servicing Capability | Robotic Servicing | Limited/None |

| Orbit | Geosynchronous (GEO) | Various |

| Flexibility | Highly Flexible and Adaptable | Limited Flexibility |

| Sustainability | Increased On-Orbit Lifespan | Limited Lifespan |

Did You Know? Northrop Grumman’s SpaceLogistics has already demonstrated its capabilities with the Mission Extension Vehicle (MEV), which successfully extended the life of an intelsat satellite.

Environmental Testing: Ensuring Reliability in Space

Environmental testing is a crucial phase in the development of the MRV. These tests simulate the extreme conditions of space, including temperature variations, vacuum, and radiation, to ensure the spacecraft can withstand the harsh environment and perform reliably throughout its mission.

Pro Tip: Environmental testing often involves vibration tests to simulate the stresses of launch and thermal vacuum tests to mimic the temperature extremes in space.

These tests validate the structural integrity and functionality of the MRV, ensuring it meets the stringent requirements for space operations.

What implications do you foresee for the future of space exploration with the advent of robotic servicing vehicles? How might these advancements affect the cost and accessibility of satellite technology?

The Evergreen Impact of Space Logistics

space logistics is revolutionizing how we manage and sustain satellites in orbit. Traditional satellites have a limited lifespan, constrained by fuel and component degradation. Robotic servicing vehicles like the MRV offer a solution to extend satellite lifespans, repair malfunctions, and even upgrade existing technology in space.

This capability is not only cost-effective but also reduces space debris by minimizing the need for new satellite launches. The implications are far-reaching, impacting everything from interaction and navigation to national security and scientific research.

Looking ahead, advancements in space logistics could pave the way for in-space manufacturing, asteroid mining, and even the establishment of permanent space stations, unlocking new opportunities for exploration and resource utilization.

Frequently Asked questions About Space Logistics

- What Is Space Logistics? Space logistics involves the transportation, maintenance, and servicing of equipment and systems in space, including satellites and other spacecraft.

- What Is The Mission Robotic Vehicle (MRV)? The Mission Robotic vehicle (MRV) is a spacecraft designed for robotic servicing of satellites in geosynchronous orbit.

- How Does Robotic Servicing Extend A Satellite’s Life? Robotic servicing can extend a satellite’s life by refueling it, repairing damaged components, or upgrading its technology, ensuring it remains operational for longer periods.

- What Are The Benefits Of On-Orbit Satellite Servicing? On-orbit satellite servicing reduces costs by extending satellite lifespans, minimizes space debris by avoiding unnecessary launches, and enhances satellite capabilities through upgrades and repairs.

- Who Is Northrop Grumman SpaceLogistics? Northrop grumman SpaceLogistics is a company specializing in providing on-orbit servicing and sustainment solutions for satellites.

Share your thoughts on this groundbreaking advancement in space logistics! Leave a comment below.

What are the potential risks associated with the widespread deployment of the NGRSS, considering the possibility of malfunction or misuse?

northrop Grumman’s next-Gen Space Robotic Servicing System: Orbital Servicing & Beyond

The Revolutionary Impact of Space Robotics

Northrop Grumman is at the forefront of revolutionizing space operations with its advanced Next-gen Space robotic Servicing system (NGRSS). This innovative technology is poised to transform how we manage & maintain satellites, address space debris, and advance in-space manufacturing. Imagine a future where on-orbit satellite servicing is routine, and the lifespan of critical space assets is considerably extended. That future is rapidly becoming a reality, thanks to the capabilities of this refined system. the NGRSS is designed to perform a variety of services, including robotic satellite servicing, orbital debris removal, and satellite refueling, making it a crucial player in the enduring use of space. Relevant search terms include: satellite servicing systems, space robotics technology, orbital debris cleanup, and in-space assembly.

key Components and Capabilities of the NGRSS

The NGRSS architecture involves several key elements working in concert to deliver remarkable capabilities. Understanding these components is crucial to grasp the full potential of the system. here are the primary components and their functions:

-

Robotic Servicing Vehicle (RSV): The primary spacecraft,equipped with advanced robotic arms and tooling designed to interact with and service client satellites. The RSV is the workhorse in this space robotic venture.

-

Payloads and Tooling: A suite of specialized instruments and robotic end-effectors that enable a wide range of services, from refueling to component replacement. The versatility of these payloads is critical.

-

Advanced Navigation and Control Systems: Sophisticated software and hardware for autonomous operations, including rendezvous, docking, and precise manipulation of satellites.

-

Ground Control and Mission Planning: A thorough ground segment to manage the entire mission lifecycle, including planning, real-time monitoring, and command execution.

The capabilities of the NGRSS are far-reaching,encompassing not just satellite servicing but also orbital debris removal,satellite life extension,and even in-space assembly. These capabilities provide immense value to both commercial and government entities operating satellites in orbit.

Detailed Look at Space Robotic Missions

The NGRSS is designed to handle diverse missions with precision, including:

- Satellite Refueling: Extending the operational lives of satellites by replenishing their fuel.

- Component Replacement: Replacing faulty components or upgrading existing ones.

- Orbital Adjustment: Repositioning satellites for optimal orbit and maintaining space situational awareness.

- Debris Mitigation: Capturing or deorbiting space debris to mitigate orbital collisions.

Northrop Grumman’s Legacy in Space Robotics

Northrop Grumman isn’t new to the space servicing game. Their expertise in this area is exemplified by their Mission Extension Vehicle (MEV) program. these vehicles have demonstrated the ability to dock and extend the lifespan of existing satellites, a important success in satellite life extension.Key to this is the long-standing involvement in the space industry as well as their extensive partnerships. The success of the MEV series has significantly paved the way for even more advanced systems like the NGRSS to take shape.

Benefits of the NGRSS

The adoption of the NGRSS offers a multitude of advantages for space users and stakeholders. These benefits include:

- Reduced Space Debris: By providing active debris removal and extending the lifespan of existing satellites, the NGRSS contributes to a cleaner and safer space environment.

- Cost Savings: Extending the lifespan of satellites reduces the need for costly replacements and launches.

- Enhanced Reliability: On-orbit repairs & upgrades can prevent failures, ensuring reliable satellite operations.

- Innovation and Advancement: By opening a variety of research and manufacturing opportunities in space, the NGRSS helps stimulate further advancement in space technology.

Real-World Examples and Case Studies of Space Robotic servicing

While the NGRSS represents the future, past projects showcase its viability and effectiveness.

The MEV projects demonstrate actual servicing, life extension and refurbishment capabilities.

Here are some key outcomes:

| Project | Outcome | Client Benefits |

|---|---|---|

| Mission Extension vehicle (MEV) | Successfully docked with and extended the life of several commercial satellites. | Significant savings on satellite mission replacement costs, optimized satellite operations |

| various Repair Missions (Conceptual) | Hypothetical component replacement and refurbishment missions. | Enhanced satellite mission resilience, greater asset investment. |

Impact on the Future of Space Exploration

The NGRSS, with its expanded capabilities, is positioned to significantly transform the future of space activity by:

- Changing the Economics of Space: Reducing the barriers to entry, thus lowering the cost of deploying satellites, leading to increased orbital investments.

- New Possibilities in Space Manufacturing: The ability to assemble large structures or manufacture advanced technologies in space becomes a reality.

- Greater Sustainability: Improving and extending the use of valuable space resources, which contributes to the long-term environmental sustainability of space activity.

Practical Tips for Space Robotics Enthusiasts

If you’re passionate about space robotics, here are a few recommendations:

- Follow industry news: monitor the developments from reputable space robotics companies like Northrop Grumman.

- Educate yourself: Study robotics,aerospace engineering,satellite technology,and related fields.

- Get Involved: Search and participate in related project and research initiatives for practical experience.

- Visit: If the chance presents itself, visit such manufacturing sites for exposure to the process.