Researchers at the Massachusetts Institute of Technology (MIT) have made significant strides in the field of biopharmaceutical production by employing artificial intelligence (AI) to enhance protein manufacturing processes. Their recent study focuses on optimizing the use of the industrial yeast Komagataella phaffii, a key player in the production of vaccines and biopharmaceuticals. This innovative approach has the potential to significantly lower development costs, making these vital drugs more accessible.

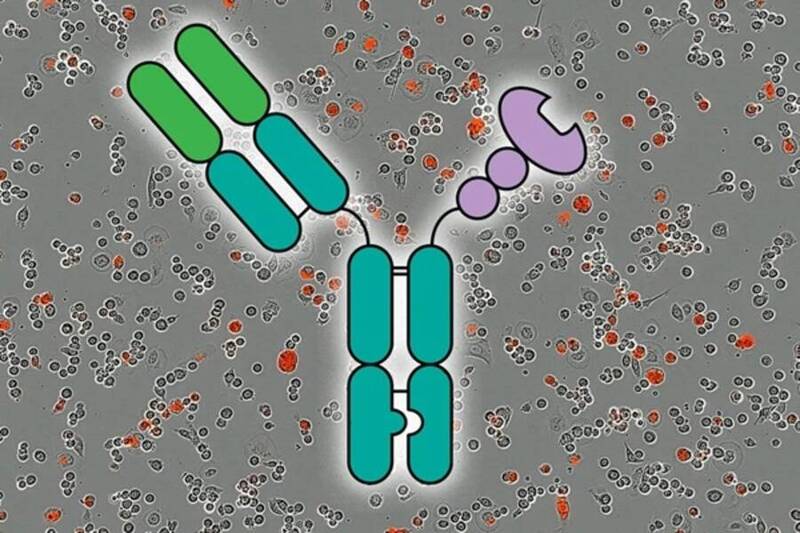

Utilizing a large language model (LLM), the MIT team analyzed the genetic coding sequences of K. Phaffii, specifically examining the codons—three-letter DNA sequences that encode amino acids. The research revealed that different organisms utilize codons in unique patterns, and the new model was trained to identify the most effective codons for producing various proteins. This optimization has led to increased efficiency in the yeast’s production of several proteins, including human growth hormone and a monoclonal antibody used in cancer treatment.

“Having predictive tools that consistently function well is really vital to help shorten the time from having an idea to getting it into production,” said J. Christopher Love, a leading professor of chemical engineering at MIT. He emphasized that reducing uncertainties in this process can save both time and costs.

Understanding Codon Optimization

Yeasts like K. Phaffii and Saccharomyces cerevisiae (baker’s yeast) are integral to the biopharmaceutical industry, generating billions of dollars in protein drugs and vaccines annually. To harness the yeast for large-scale protein production, researchers typically extract genes from other organisms, modify them, and integrate them into the yeast’s genome. This complex procedure can account for 15 to 20 percent of the total commercialization cost of biologic drugs.

Traditionally, optimizing the DNA codon sequence for a target protein has been a labor-intensive task. However, the MIT researchers aimed to streamline this process using machine learning techniques. Their approach involved analyzing how different codons are used in the yeast genome to determine which combinations would yield the best results for protein production.

Innovative Machine Learning Techniques

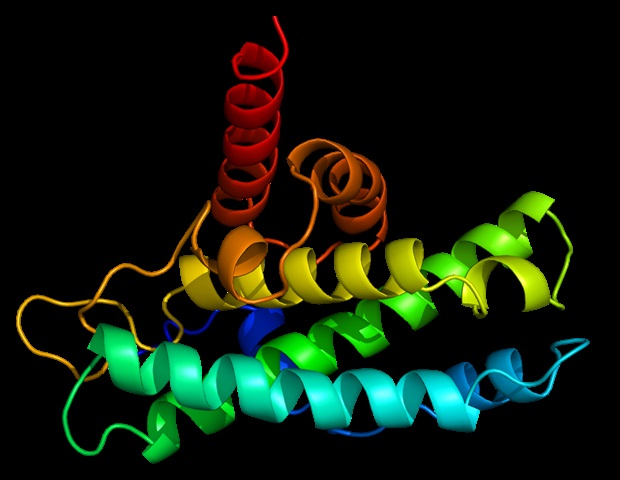

The research team employed a sophisticated encoder-decoder model, which is a type of large language model. Rather than processing text, the model was designed to analyze DNA sequences, learning the relationships between codons that are utilized in specific genes. Training data for the model was sourced from a publicly available dataset, encompassing amino acid and DNA sequences of around 5,000 proteins naturally produced by K. Phaffii.

The model’s ability to “learn” the syntax of codon usage allowed it to predict optimal sequences for six different proteins, including human serum albumin and trastuzumab, a treatment for cancer. The results were promising: the model outperformed existing commercial codon optimization tools for five out of the six proteins tested.

Love noted that the model not only understood the language of codons but also contextualized this understanding with biochemical features, enhancing the reliability of its predictions. “Not only was it learning this language, but it was also contextualizing it through aspects of biophysical and biochemical features,” he said.

Implications for Biopharmaceutical Production

The findings from this research hold the promise of transforming how biologic drugs are developed. K. Phaffii is already used to produce numerous commercial products, such as insulin and hepatitis B vaccines, and this optimization technique could further improve production efficiency and reduce costs across the board.

The implications of this study extend beyond just K. Phaffii. The researchers also tested their model on datasets from other organisms, including humans and cows, indicating that tailored models for different species could enhance protein optimization efforts significantly.

The research has been funded by several initiatives, including the Daniel I.C. Wang Faculty Research Innovation Fund at MIT and the Koch Institute. As researchers continue to refine these models, the potential for more efficient and cost-effective biopharmaceutical manufacturing is becoming increasingly tangible.

As the field progresses, the availability of these advanced optimization tools could lead to faster development times for new biologic drugs, ultimately improving patient access to life-saving treatments. For those interested in the future of protein production and AI in biotechnology, this is a space to watch.

the intersection of AI and biopharmaceutical manufacturing is paving the way for innovative solutions that promise to enhance efficiency and reduce costs in drug production. For further updates and insights, feel free to share your thoughts.