Macy’s Bets Big on Automation with New $640 Million Warehouse

Table of Contents

- 1. Macy’s Bets Big on Automation with New $640 Million Warehouse

- 2. Revitalizing a Retail Icon

- 3. Streamlining the Supply Chain

- 4. The Rise of Automated Retail

- 5. Faster Deliveries, Reduced Costs

- 6. The Future of Retail Logistics

- 7. frequently Asked Questions about Macy’s Automation

- 8. How will Macy’s $640 million investment in warehouse automation specifically impact its ability to compete with retailers like Amazon during peak shopping seasons?

- 9. Macy’s Launches $640 Million High-Tech Robotics upgrade for Advanced Warehouse Automation

- 10. The Scale of the Investment & Key Technologies

- 11. Impact on Fulfillment Speed & Capacity

- 12. Specific Automation Technologies Deployed

- 13. Benefits of Macy’s Robotics Investment

- 14. Real-World Examples & Industry Trends

- 15. Challenges & Considerations for Warehouse automation

New York, NY – Macy’s is aggressively pursuing a turnaround strategy centered on advanced automation, recently unveiling a sprawling, $640 million distribution center in North carolina. The 2.5 million-square-foot facility represents the retailer’s largest and most technologically advanced investment to date, designed to dramatically improve order fulfillment speed and efficiency.

Revitalizing a Retail Icon

Under the leadership of Chief Executive Officer Tony Spring, Macy’s has been working to overcome years of declining sales. The company’s approach involves a thorough overhaul of its store portfolio and a notable streamlining of its supply chain operations. This new warehouse is a critical component of that strategy, representing a pivot towards faster, more reliable delivery for its customers.

Streamlining the Supply Chain

Over the past two years, Macy’s has proactively closed one distribution center and shuttered two third-party logistics facilities. Together, the company has been integrating automation into existing warehouses to expedite online order processing and ensure consistent product availability in stores. According to industry analysts, these moves demonstrate a commitment to adapting to the evolving demands of the modern consumer.

The Rise of Automated Retail

Macy’s faces considerable competition from discount retailers, online marketplaces, and fast-fashion brands, all vying for consumer spending with aggressive pricing and expedited shipping. To remain competitive, retailers must meet escalating customer expectations regarding delivery speed and order accuracy.According to a recent report by Statista, over 65% of consumers expect delivery within three days of placing an online order.

| Key Metric | Previous System | New Automated System |

|---|---|---|

| Order Fulfillment Time | 1.5 Days | Less than 1 Day |

| Packages Per Order | Multiple Possible | Fewer |

| Inventory Capacity | Limited | Increased |

Logistics experts emphasize the importance of adapting to these changing consumer behaviors. Thomas Goldsby, a professor of logistics at the University of Tennessee, notes that today’s shoppers demand “limitless assortment, competitive pricing, simple ordering, order visibility, timely delivery, and effortless returns.”

Faster Deliveries, Reduced Costs

Macy’s executives report that the new North Carolina facility is significantly reducing order fulfillment times. Senior Vice President of Supply Chain, Sean Barbour, explained that orders are now completed in under 24 hours on average, a substantial improvement from the previous 36-hour timeframe. Moreover, increased inventory capacity allows Macy’s to consolidate multiple items into single shipments, reducing shipping costs and the number of tracking numbers customers receive.

“Customers want to see as few tracking numbers as possible,” Barbour stated.”This also benefits Macy’s financially as shipping multiple packages per order is expensive.”

recent earnings reports suggest Macy’s turnaround efforts are gaining traction, with comparable-store sales increasing by 0.8%, exceeding analyst expectations. This resurgence is partially attributed to the company’s “reimagine” store modernization program, which incorporates AI-driven inventory management and enhanced store organization.

The Future of Retail Logistics

The investment in the automated warehouse underscores a broader trend in the retail industry. companies are increasingly recognizing the crucial role of technology in optimizing supply chains and enhancing customer experiences. Expect to see more retailers prioritize automation, AI, and data analytics to meet the demands of an increasingly competitive market. The integration of robotics and machine learning can lead to significant efficiency gains, reduced operational costs, and improved order accuracy.Moreover, sustainable delivery options and last-mile logistics solutions will become even more critically important as consumers prioritize environmental obligation.

frequently Asked Questions about Macy’s Automation

- What is Macy’s primary goal with this new warehouse? Macy’s aims to significantly reduce order fulfillment times and enhance its supply chain efficiency.

- How is Macy’s addressing challenges from competitors? The company is investing heavily in automation and modernization to offer competitive pricing and faster deliveries.

- What impact will this have on macy’s shipping costs? the new warehouse is designed to consolidate shipments, reducing the total number of packages shipped per order and lowering associated costs.

- What role does technology play in Macy’s turnaround strategy? Technology, particularly AI-driven inventory management, is central to the “Reimagine” store modernization program.

- How does this warehouse benefit customers? Customers will experience quicker delivery times, fewer packages, and improved order accuracy.

What are yoru thoughts on the future of automated warehouses in retail? Do you believe this investment will be enough to secure Macy’s position in the market?

How will Macy’s $640 million investment in warehouse automation specifically impact its ability to compete with retailers like Amazon during peak shopping seasons?

Macy’s Launches $640 Million High-Tech Robotics upgrade for Advanced Warehouse Automation

The Scale of the Investment & Key Technologies

Macy’s is making a significant bet on the future of retail fulfillment with a $640 million investment in advanced warehouse automation. This isn’t a simple upgrade; it’s a comprehensive overhaul leveraging cutting-edge robotics, automation technology, and AI-powered logistics across its nationwide fulfillment network. The initiative focuses on automating key processes within its distribution centers, aiming to drastically improve speed, accuracy, and efficiency in order fulfillment.

The core of this investment centers around partnerships with leading robotics firms, including:

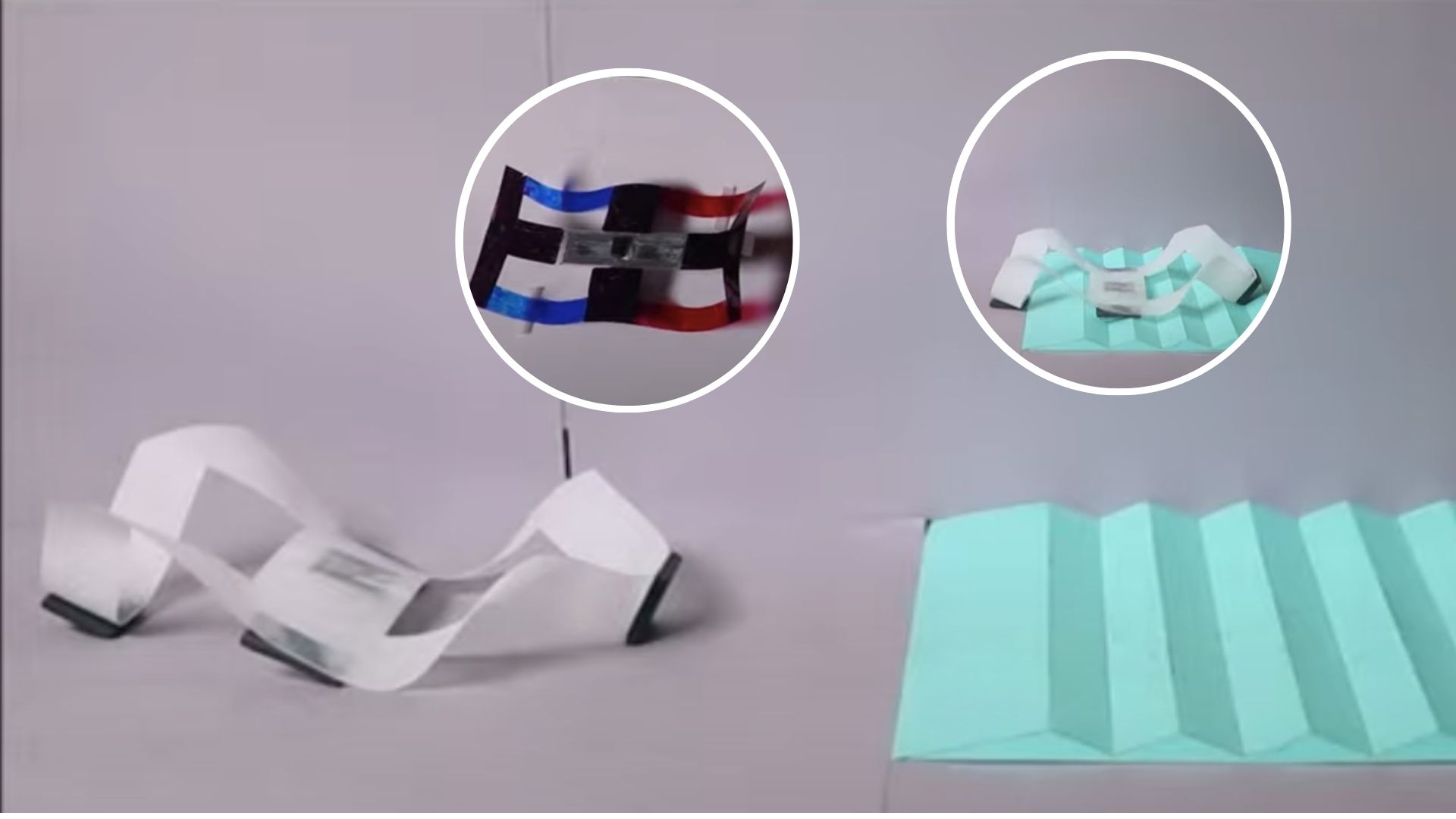

* Attabotics: Implementing their 3D robotic fulfillment systems to increase storage density and order picking speed.

* GreyOrange: Deploying their robotic sorters and autonomous mobile robots (AMRs) to streamline package handling.

* Locus Robotics: Expanding their AMR fleet for collaborative picking and transportation tasks.

These aren’t isolated deployments. Macy’s is strategically integrating these technologies to create a cohesive, end-to-end automated warehouse solution.

Impact on Fulfillment Speed & Capacity

The primary goal of this warehouse automation project is to significantly reduce order fulfillment times. Currently, the average order takes several days to reach the customer. With the new systems in place, Macy’s anticipates:

- Faster Order Processing: Robotics will accelerate the picking, packing, and sorting stages.

- Increased Throughput: Automated systems can handle a higher volume of orders,especially during peak seasons like Black Friday and the holidays.

- Reduced Errors: Automation minimizes human error,leading to fewer mis-shipped items and improved customer satisfaction.

- Expanded Capacity: The increased efficiency allows Macy’s to handle growing online sales without needing to drastically expand its physical warehouse footprint.

This translates to a more responsive supply chain and a better shopping experience for customers.The investment directly addresses the growing demand for e-commerce fulfillment and same-day delivery options.

Specific Automation Technologies Deployed

Beyond the headline robotics partnerships, macy’s is implementing a range of supporting technologies:

* Automated Storage and Retrieval Systems (AS/RS): High-density storage solutions that use robots to retrieve and store items.

* conveyor Systems: Smart conveyor networks that route packages efficiently throughout the warehouse.

* Warehouse Management Systems (WMS): Refined software that orchestrates all warehouse activities, including inventory management, order processing, and shipping.

* Machine Learning (ML) & Artificial intelligence (AI): Algorithms that optimize warehouse layout, predict demand, and improve robotic performance.

* computer vision: Used for quality control, damage detection, and accurate item identification.

These technologies work in concert to create a truly smart warehouse surroundings.

Benefits of Macy’s Robotics Investment

The $640 million investment isn’t just about speed and efficiency. It’s about building a more resilient and adaptable supply chain. Key benefits include:

* Cost Reduction: Automation reduces labor costs and minimizes errors, leading to significant savings.

* Improved Labor Utilization: Employees can focus on higher-value tasks, such as customer service and problem-solving.

* Enhanced Scalability: The automated systems can easily scale to meet changing demand.

* Greater Supply Chain Visibility: Real-time data and analytics provide insights into warehouse operations.

* Competitive Advantage: Faster, more accurate fulfillment gives Macy’s a competitive edge in the crowded retail market.

Real-World Examples & Industry Trends

Macy’s isn’t alone in embracing warehouse robotics. Companies like Amazon, Walmart, and Target have already made substantial investments in automation.

* Amazon Robotics: pioneered the use of Kiva robots to revolutionize its fulfillment centers.

* Walmart Automation: Implementing micro-fulfillment centers and automated grocery picking systems.

* Target’s Sortation Centers: utilizing robotics to sort packages for last-mile delivery.

These examples demonstrate the growing trend towards intelligent automation in the retail industry.The demand for faster, cheaper, and more reliable fulfillment is driving this conversion.The rise of fulfillment as a service is also influencing these investments, as retailers seek to outsource complex logistics operations.

Challenges & Considerations for Warehouse automation

Implementing such a large-scale automation project isn’t without its challenges:

* Integration Complexity: Integrating new robotics systems with existing infrastructure can be complex and time-consuming.

* Initial Investment Costs: The