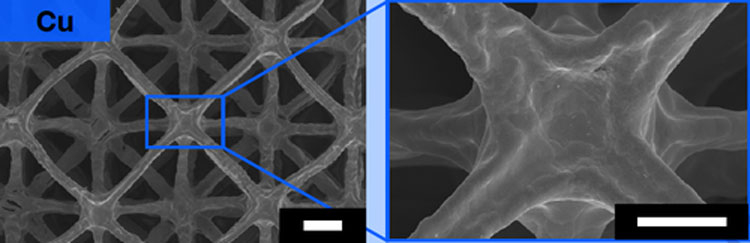

Caltech engineers developed a method of 3D printing from metals and alloys with a resolution that, in some cases, is an order of magnitude smaller than was previously possible. The minimum element size has been reduced to 40 microns, paving the way for the production of tiny components for microelectronic mechanical systems (MEMS) that can be applied to a wide range of devices, from sensors to chip heat dissipation systems.

Image Source: Bob Paz

Traditionally, 3D printing of metal products relies on layer-by-layer sintering of metal powders with a laser beam. At the same time, the high thermal conductivity of metals makes it difficult to increase the resolution – heating occurs quickly, and no matter how you focus the laser, more powder is sintered in the projection area than the digital model provides. Scientists from Caltech solved this problem in an interesting way – at the stage of printing a model, they proposed to abandon metals and a laser.

The model is still created layer by layer on a 3D printer, but not from laser-heated powder metal, but from a polymer hydrogel with layer-by-layer fixing with ultraviolet light. After creating the model, it is placed in an aqueous solution of metal salts, in which metal ions penetrate into the hydrogel. After saturation of the model with salts, the model is annealed. The annealing temperature is chosen below the melting point of the metal, but it is still high enough (700–1100 °C) to completely burn out the hydrogel.

After annealing, a metal model remains with an element resolution even lower than that of a hydrogel matrix. And if the method of direct laser 3D printing can create metal parts with a minimum resolution of 100 microns, then the use of a matrix increases the resolution of printing metal models up to 40 microns. It is twice as thin as a human hair.

Copper model following annealing

3D Architech was formed by Caltech to license the new printing technology to anyone interested. Biotechnology, chip cooling, sensors, robotics – all these disciplines and many others need to mass-produce miniature metal products that cannot be made in the traditional way – casting, milling, forging, and so on.

If you notice an error, select it with the mouse and press CTRL + ENTER.